In-depth Analysis How to Create Best-selling Packaging for Customized Aerosol Cans?

I. In-Depth Industry Insights: Market Drivers for Custom Packaging

1. Consumer Psychology Research

-

7-Second Rule: Consumers make purchase decisions in just 7 seconds at the shelf

-

Haptic Marketing: 85% of consumers associate packaging texture with product quality

-

Color Psychology:

-

Gold/Black: Conveys luxury (used by 78% of premium brands)

-

White/Blue: Communicates purity (used by 65% of healthcare products)

-

2. Global Market Heatmap

| Region | Popular Customization Needs | Representative Case Studies |

| Europe | Eco-friendly recyclable designs | Lush "Naked" aerosol cans |

| North America | Interactive packaging | Coca-Cola "Scan-to-Win" spray |

| Asia | Mini portable versions | Shiseido 15ml travel perfume sprays |

II. Advanced Material Science & Structural Design Guide

1. Innovative Material Matrix

| Material Type | Characteristics | Best Applications |

| Medical-grade 316L Stainless Steel | Superior corrosion resistance | Premium perfumes, pharmaceuticals |

| Chrome-Plated Aluminum | Mirror-like reflective finish | Limited edition cosmetics |

| Transparent PETG | Content visibility | Food sprays, essential oils |

2. Breakthrough Structural Designs

-

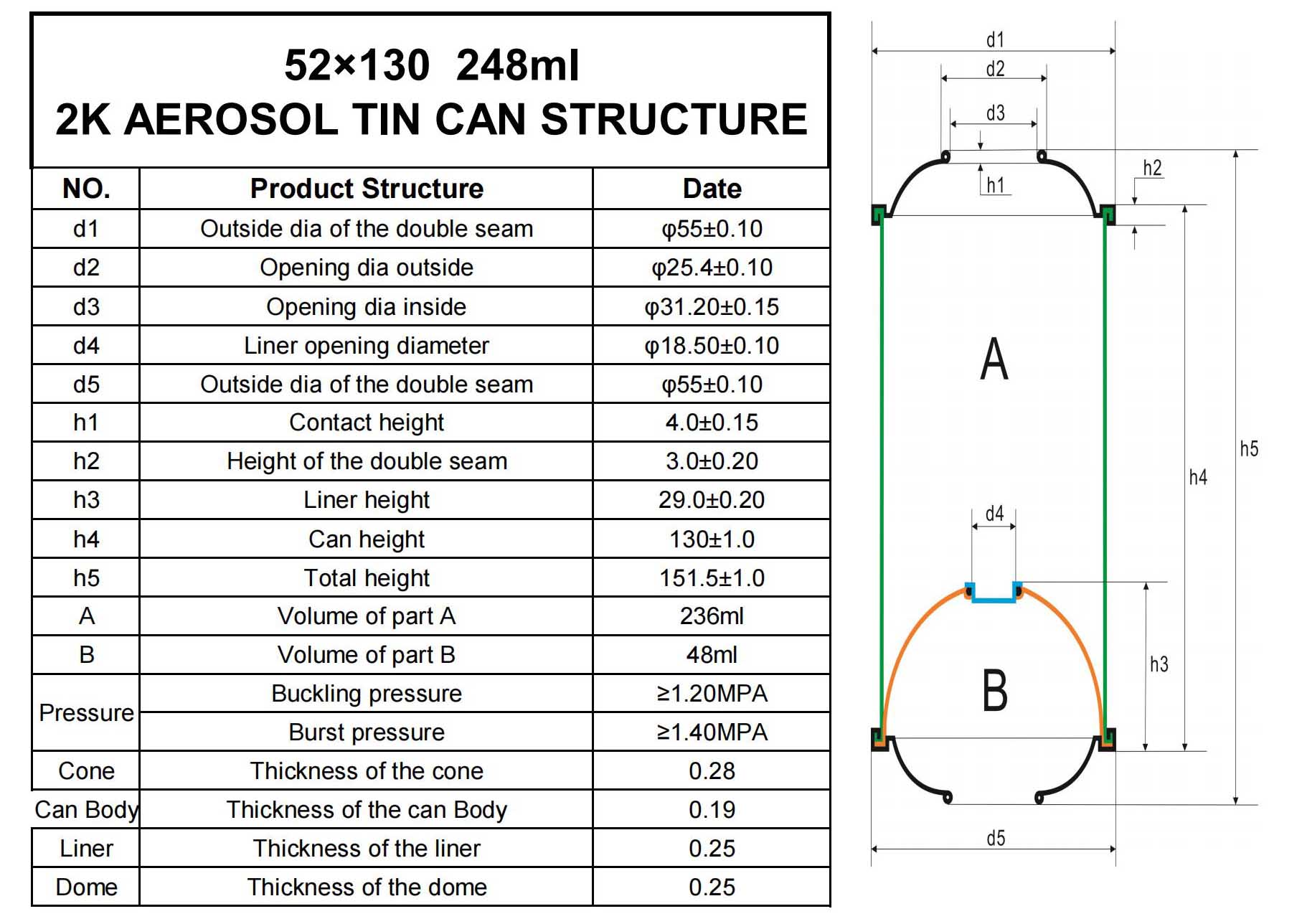

Dual-Chamber Systems (2k aerosol tin can):

-

Patented separation technology

- 🎨 Free design consultation: Our engineers can provide 1v1 scheme optimization

- 📦 Low MOQ: 2K aerosol can accept 1,000pcs MOQ

-

|

|

-

Replaceable Cartridge Systems:

-

Main body + interchangeable inner containers

-

Case study: Dior's "Refillable Elegance" perfume collection

-

3. Ergonomic Innovations

-

Anti-slip texture design (friction coefficient 0.4-0.6)

-

Disability-friendly features:

-

One-handed operation mechanism

-

Braille + voice guidance labels

-

III. Comprehensive Printing Technology Analysis (With Cost-Benefit Assessment)

1. Cutting-Edge Printing Technologies Compared

| Technology | Resolution | Color Range | Minimum Line Width | Suitable Substrates | Price Premium |

| Digital UV | 1200dpi | Full color | 0.1mm | All materials | +$0.09/can |

| Nano Printing | 5000dpi | 10^8 colors | 50nm | Smooth surfaces | +$0.34/can |

| 3D Embossing | N/A | Single color | 0.3mm | Metal/Plastic | +$0.27/can |

2. Special Effect Implementation

-

Thermochromic Inks: Responsive range -15℃~60℃

-

Photochromic Inks: 3+ color dynamic shifts

-

Scent Microcapsules: Continuous fragrance release for 6-12 months

3. Cost Optimization Strategies

-

Gang-run printing: Reduces small-batch costs by 30-45%

-

Partial finishing: Premium effects only on key areas

-

Standardized color systems: Minimize spot color usage

IV. Global Compliance Master Guide

1. International Certification Systems

-

Food-grade: FDA 21 CFR, EU 10/2011

-

Pharmaceutical-grade: USP <661>, EP 3.2

-

Transportation safety: UN/DOT 6P certification

2. Regional Requirements

-

EU: REACH SVHC testing (<0.1%)

-

USA: California Proposition 65

-

China: GB 4806.1 food contact material standards

V. Deep Dive into Success Stories

Case Study 1: Nivea Men Deodorant Spray

-

Innovation: Magnetic base design (prevents rolling in showers)

-

Results: 19% market share increase

-

Technical Details:

-

Embedded neodymium magnets (corrosion-treated)

-

Rubber anti-slip ring base

-

Case Study 2: Tiffany & Co. Limited Edition Perfume

-

Innovation: Jewelry-grade electroplating

-

Results: 300% price premium over standard products

-

Specifications:

-

Multi-layer plating (copper+nickel+rhodium)

-

Surface roughness Ra≤0.2μm

-

VI. Future Lab: 2025-2030 Technology Outlook

-

Smart Packaging:

-

E-ink displays showing remaining quantity

-

IoT-connected auto-replenishment

-

-

Bio-Materials:

-

Algae-based can bodies (100% biodegradable)

-

-

Multi-Sensory Integration:

-

Haptic feedback nozzles (pressure-sensitive)

-

Voice-guided usage instructions

-

VII. Supplier Selection Checklist

□ ISO 15378 pharmaceutical packaging certification

□ MOQ alignment with requirements

□ Prototyping lead time (industry average: 7-15 working days)

□ Full lifecycle carbon footprint reporting

□ Case study relevance to your needs

VIII. Failure Case Analyses

-

Case A: Gold foil peeling incident

-

Root cause: Skipped RCA abrasion testing

-

Loss: $350,000 recall cost

-

-

Case B: Can deformation issues

-

Root cause: Insufficient wall thickness design

-

Lesson: Mandatory FEA simulation required

-